Offset

For sheet-fed Traditional- & UV-Offset presses. In our OFFSET -products the film is attached to the cardboard backer by two gluelines.

Product properties

STAFIX®STATIC is a glue-free sticker material that adheres to almost any clean, even surface with a static charge. the material adheres on average for 3 months and is easy to apply and removable without leaving any residue.

The material adheres on the unprinted side only.

STAFIX®STATIC OFFSET is available in white and clear and comes in sheets. The material consists of two layers:

- 50 microns thick, polypropylene film. (Top layer)

- 180 g/m2 cardboard backer. (Bottom layer)

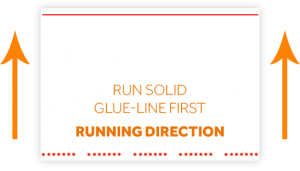

The film is attached to the cardboard backer by two gluelines: A solid glueline in the front of the sheet, and a dotted glue line in the back of the sheet (see picture).

STAFIX®STATIC film is 100% recyclable as a grade 5 plastic and doesn’t release toxic gases into the environment if incinerated. The cardboard used for the backer is PEFC certified.

SHELF LIFE

In the sealed original package, unprinted STAFIX®STATIC sheets can be stored up to 12 months following our storage guidelines.

Packaging and formats

| FORMAT | SHEETS / REAM | SHEETS / PALLET |

|---|---|---|

| 320 x 450mm | 200 | 4000 |

| 480 x 650mm | 200 | 2000 (in reams) 2500 (bulk) |

| 707 x 1000mm | 200 | 2000 |

| Custom format | 2000 |

| PRODUCT DATA | ||||

|---|---|---|---|---|

| WHITE | CLEAR | |||

| FILM | BACKER | FILM | BACKER | |

| Weight (g/m2) | 36.3 | 180 | 45.5 | 180 |

| Thickness (mm) | 0.05 | 0.260 | 0.05 | 0.260 |

| Total Weight (g/m2) | 216.3 | 225.5 | ||

| Total Thickness (mm) | 0.310 | 0.310 | ||

| Stafix® Product code | ST-50PP2W180A | ST-50PP1C180A | ||

FORMAT TOLERANCE

Size tolerance is 0 / +5mm in machine and cross direction

Sheet flatness tolerance is 8mm

CUSTOM SIZE ORDERS

For larger quantities, cost efficiency can be achieved by producing tailored size sheets. Please consult us regarding minimum quantities and delivery times.

Storage

| STORAGE CONDITIONS | PRINTING CONDITIONS | |

|---|---|---|

| Humidity (RH) | 25% to 50% | 50% to 60% |

| Temperature | 20°C to 27°C | |

Store the unwrapped STAFIX®STATIC OFFSET in the original package at 25% to 50% relative humidity and 20°C to 27°C temperature. The material should remain sealed in the original wrap until the Stafix®STATIC material has warmed up to print-room temperature.

The print-room recommended relative humidity is 50% to 60% and the temperature 20°C to 27°C.

The warming-up time depends on the pallet weight and the temperature difference between the warehouse and the print-room, see table below for more details:

| PACKAGING | WEIGHT | TEMPERATURE DIFFERENCE (°C) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| FORMAT | KG (APPROX) | 5° | 10° | 15° | 20° | 25° | 30° | 35° | 40° | HOURS | |

| 320 x 450 mm | Full pallet (2000 sheets) | 80 kg | 4 | 12 | 18 | 24 | 30 | 34 | 38 | 40 | |

| 480 x 650 mm | Full pallet (2000 sheets) | 160 kg | 8 | 24 | 36 | 48 | 60 | 68 | 76 | 80 | |

| 707 x 1000 mm | Full pallet (2000 sheets) | 380 kg | 14 | 33 | 47 | 61 | 75 | 84 | 94 | 98 | |

Once the STAFIX®️STATIC Offset sheets have reached the same temperature as the print room you can unwrap the pallet. Let the material acclimatise without the wrap / plastic bag for 2 hours prior to printing for better runnability and efficient feeding.

After use re-seal the remaining unused material in the original package. Sudden changes of temperature and/or humidity may cause the cardboard to change size, and this could wrinkle the film.

Do not use a Total Ink Coverage (TIC) greater than 240%. Use the Under Colour Removal (UCR) and Grey Component Replacement (GCR) if needed. Heavy deposits of ink should be avoided, especially near the edges of the artwork, to prevent the film from curling or rippling. Leave an unprinted border at the edges of the artwork if possible. Do not overlap a combination of two or more solid colours. Heavy layers of ink may cause the film to swell.

For pictures a raster of 60 – 70 l/cm is recommended.

Place the artwork close to the front of the sheet and leave an unprinted area on the tail of the sheet. The colour bar should be placed 2cm from the tail edge of the sheet.

Make sure that black text consists of only 100% black for better registration.

CLEAR MATERIAL

When printing an artwork on the clear material that will be used for window advertising, print the image mirror-wise and apply an additional covering white layer to reduce the transparency. Rasterize the covering white to 95%. Additionally to the covering white you can use 240% maximum TIC on the colour build.

The sticker or poster is always installed from the unprinted side to the glass. The material adheres only from the unprinted side.

Not all the presses have white inks available; consult with your printing house beforehand.

Please see the table below for the maximum printable area by product:

| FORMAT | MAXIMUM PRINTABLE AREA |

|---|---|

| 320 x 450 mm | 300 x 440 mm |

| 480 x 650 mm | 440 x 640 mm |

| 707 x 1000 mm | 640 x 990 mm |

Always run a test with the right inks and right conditions before printing a commercial job, specially for the first time printing on STAFIX®STATIC

POSITION OF THE PRINTING PLATE

Make sure the artwork is placed close to the front of the sheet and that there is an unprinted area on the tail of the sheet for better registration. The colour bar should be placed 2cm from the tail edge of the sheet.

FEEDING

Fan the sheets properly prior to loading. This is very important for efficient feeding. Run in short lifts of between 200-250 sheets. Set the feeder settings for printing on thick materials. The STAFIX®STATIC OFFSET film is glued on to a cardboard by two glue lines from the long sides of the sheet. DO NOT CUT THE GLUE LINES BEFORE PRINTING. The sheet sizes 480x650mm and 707x1000mm have a cardboard margin on the tail edge of the sheet to allow for better feeding.

Strong air supply is essential for feeding STAFIX®STATIC. Position the feeder air blowers so that the air separates the first 10-15 sheets to minimize blocking. Use additional side blowers if possible, and position them at the front of the stack. Run at a maximum press speed of no more than 5000-7000 sheets per hour.

Strong air supply is essential for feeding STAFIX®STATIC. Position the feeder air blowers so that the air separates the first 10-15 sheets to minimize blocking. Use additional side blowers if possible, and position them at the front of the stack. Run at a maximum press speed of no more than 5000-7000 sheets per hour.

Print with low levels of water. STAFIX®STATIC absorbs no water and therefore very little water is needed (roughly less than half of what would be required with paper). If possible use metal plates that carry minimal water. The plate requires only enough water to keep the surface wet. For oxidative inks keep the alcohol level from 10 to 15% and follow the guidelines from the ink supplier. The acidity of the dampening solution should not be set too high, (PH value approx. 5.5). Set the print impression pressure as light as possible in order to avoid stretching of the film.

INK USAGE AND RECOMENDED INKS

Avoid applying heavy layers of ink. Keep the ink density lower than when printing on coated paper. Use ONLY our recommended inks suitable for printing on thin polypropylene substrates. Foil inks including mineral oils may cause the film to swell. Avoid using other inks, drying pastes or additives.

STAFIX®STATIC OFFSET recommended inks are:

| RECOMMENDED INKS | |

|---|---|

| TRADITIONAL OFFSET (OXIDATIVE INKS) | UV-OFFSET (UV-CURABLE INKS) |

| Flint Group Novaplast® BIO | Hostmann-Steinberg (NewV® poly series) |

| Sun Chemical SunTec® Foils | Sun Chemical (Suncure® Starluxe) |

Drying

TRADITIONAL OFFSET

Do not use IR dryers; the intensity of the IR lamps may cause the film to expand due to excessive heat. Additionally it may also extend the drying time. Use a larger grain powder about 40 – 50 microns to facilitate drying. Larger grain powder allows more air to pass between the sheets and therefore means faster drying.

Dry the sheets in stacks of 200-250 sheets. Offsetting can occur if stacks are too large or the powder grain size is too small. Too large stacks may also obstruct airflow slowing down significantly drying time. Plan for 24 – 48 hours of drying time. Make sure the drying room has proper ventilation; this will speed up the drying process.

UV-OFFSET

Adjust the UV-lamps to a minimum level that still cures the inks but does not wrinkle the film. The heat of the lamps should increase progressively in the running direction of the material, applying less heat on the first lamps and more heat on the last lamps before delivery. When using a hybrid-printing machine turn off the IR lamps.

STATIC ELIMINATORS

Do not use any antistatic devices including sprays, tinsel, or on-press electronics. These will reduce the static charge loaded in the material.

COATINGS

Do not use any varnish or aqueous coatings! Coatings will eliminate the static charge and curl the material.

Post-press

STAFIX®STATIC sheets can be die-cut and kiss-cut. Avoid long thin shapes as they might curl away from the surface and round the inner corners because the inner-sharp corners might cause the film to tear. Perforating, binding and direct mail inserting is also possible. When trimming, use sharp, nick-free blades. Do not cut the glue lines in order to allow for auto-feeding.

PACKING & SHIPPING

Protect the products well from humidity and dust when sending the finished goods to your client. Avoid packing the material with products that emit VOC’s (Volatile Organic Compounds / Solvents) as they will reduce the static charge. Do not pack the material using vacuum-sealed packaging; the freshly printed ink can also emit VOC’s.