STATIC

The magic charge

STATIC has an ingenious design that utilizes static charge to connect. This means there is no glue whatsoever, allowing the material to be removed and repositioned repeatedly. Place, move, and replace — it doesn’t get any easier than this.

STATIC in a nutshell

- Self-adhesive material adhering by a static charge

- PVC-free, glue-free, and residue-free

- Reusable and recyclable

- Indoor lifespan 3 months

- Face stock material: PP

-

3 months indoor

-

Residue free

-

Bubble free

-

Removable

-

Ultra thin

-

Recyclable as grade 5 plastic

Where to use STATIC

STATIC is perfect for short and mid-term ads, promotions, and decorations with quick turnover. It is suitable for sensitive surfaces like TV screens and white-label products, and ideal for retail ads in beverages, frozen food, ice creams, pharmaceuticals, and seasonal promotions.

-

1

Windows

-

2

Fridges and freezers

-

3

TV’s and computer screens (sensitive surfaces)

-

4

Walls Doors Counters

Formats and packaging

Offset | white, clear | sheets

707 x 1000 mm | bulk pallets

480 x 650 mm | bulk pallets

320 x 450 mm | bulk pallets

HP Indigo | white, clear | sheets

320 x 460 mm | 100 sheets / box

530 x 750 mm | 100 sheets / box

UV-inkjet | white, clear | reels

700 mm x 50 m | 1 reel / box

700 mm x 100 m | 1 reel / box

Printing Guidelines

- ⚠️ Important Notice! Printing on static film differs from printing on plastic. Carefully follow our Technical Printing Guidelines appropriate to your printing technique below to ensure proper use of the material. In the product manual we uncover segments such as:

-

- Product Properties

- Designing and Pre-press

- Storage

- Printing

- Postpress

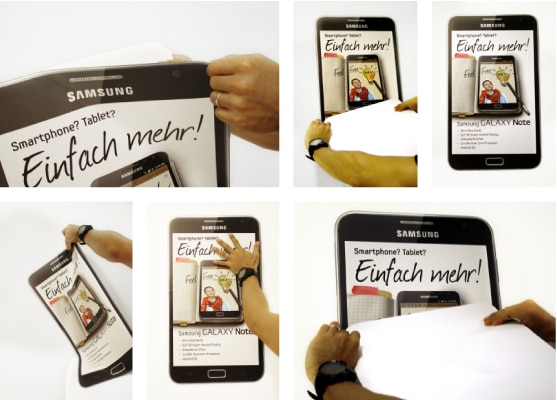

Use and installation

STAFIX®STATIC sticks to almost any dry clean surface such as: glass, marble, wood, plastic, metal etc. It does not stick to textiles or other porous surfaces. On average, STAFIX®STATIC will adhere for three months to a surface. The less STAFIX®STATIC is repositioned during this time, and the smoother the surface is, the longer it will stay attached. The installation of STAFIX®STATIC is as easy as it gets: Just peel the film off the backer, place it wherever you want, quickly brush over it for optimum adhesion – that´s it. No need for careful, time consuming placing and smoothening and no more cleaning of surfaces after installation!

The film will increase its’ adhesion strength after some time but it can be easily removed at any time without leaving any residue.

- Make sure the surface is clean. If needed clean the surface but do not use detergent or chemicals.

- Peel the film from the backer and place it on the surface from the unprinted side.

- Remove the air between the film and the applied surface to assure strong adhesion. You can use the cardboard backer for this.

If you want to display the image through a glass window from inside to the outside (Shop display) it is strongly recommended to use the transparent film.The film should be printed ‘mirror-wise’, so the unprinted side would be adhered to the glass. The film will stick on the inside of the window with visibility from the outside.

- Make sure the surface is clean. If needed clean the surface but do not use detergent or chemicals.

- Peel the film from the backer and place it on the surface from the unprinted side.

- Remove the air between the film and the applied surface to assure strong adhesion. You can use the cardboard backer for this.

For large posters or banners exceeding 1m in length is recommended to do the installation with assistance of another person to avoid the film being wrinkled or catching dust and dirt from the floor. Apply the film always from the unprinted side!

- Make sure the surface is clean. If needed clean the surface but do not use detergent or chemicals.

- Peel the film from the backer and place it on the surface from the unprinted side with assistance of another person.

- Remove the air between the film and the applied surface to assure strong adhesion. You can use the cardboard backer for this.

See Stafix products in person

Order free Stafix product samples and discover the sustainable future of self-adhesive POS materials. Our products were developed to supercharge your campaigns.